Your steps to a reliable coating of your superyacht

Your Idea

Finding the Yard

Start of Building

SANDBLASTING / CORROSION / PROTECTIOn

FILLING/FAIRING

PRIMING/COATING

Handover

Operation

INSTRUCTION OF THE CREW

AFTER ONE YEAR

AFTER FOLLOWING YEARS

STATUS SURVEY

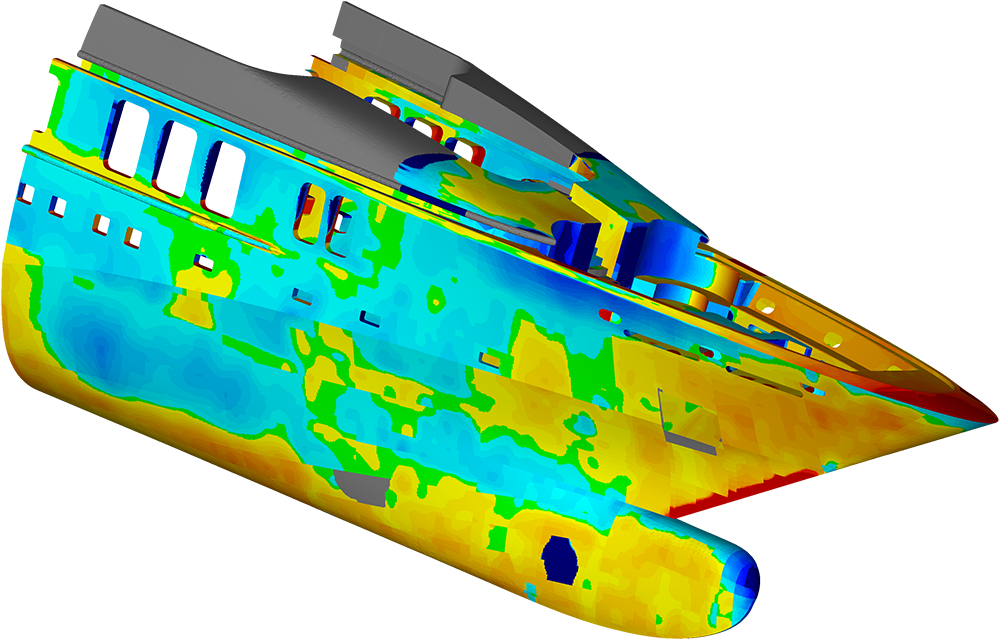

Wrede 3D Scan

Supervision of hull/superstructure

WHY WREDE CONSULTING?

- We work towards minimizing any deviations due to welding distortion, inexact shoring elements and temperature fluctuations

- We are the only company offering a precise determination of the actual dimensions during and after construction

- We perform a precise analysis on the surfaces before coating to optimize material deployment

WHAT WE DO

- Make deviations between CAD and status visible to enable specific structural corrections

- Reduce fillers, weight and coasts by realizing smoother steel surfaces

- Work closely with suppliers to optimize layer thicknesses and material selection

BENEFITS OF USING THE 3D SCAN

- Determining the ideal filler thickness

- Opportunity to perform exact inspections

- Creating a basis for supervision of subcontractors

- Comparing CAD with status

- Performing exact analyses, even without drawings or models

- Producing design drawings for fitted parts in hull and superstructure

- Creating 3D models for older vessels

- Examination of sections and components before assembly